With the integration of smart agricultural machinery, IoT, and AI technology, agricultural automation is deeply transforming traditional farming methods. The auto steering system, as a key component of precision agriculture, is becoming a driving force behind agricultural efficiency, precision, and sustainability.

In seeding, for example, the auto steering system equipped with RTK precision positioning can achieve centimeter-level navigation, reducing overlap and skips, saving 10%-30% on seed and fertilizer usage. The system also cuts fuel waste caused by path overlap, making farm operations more efficient and environmentally friendly.

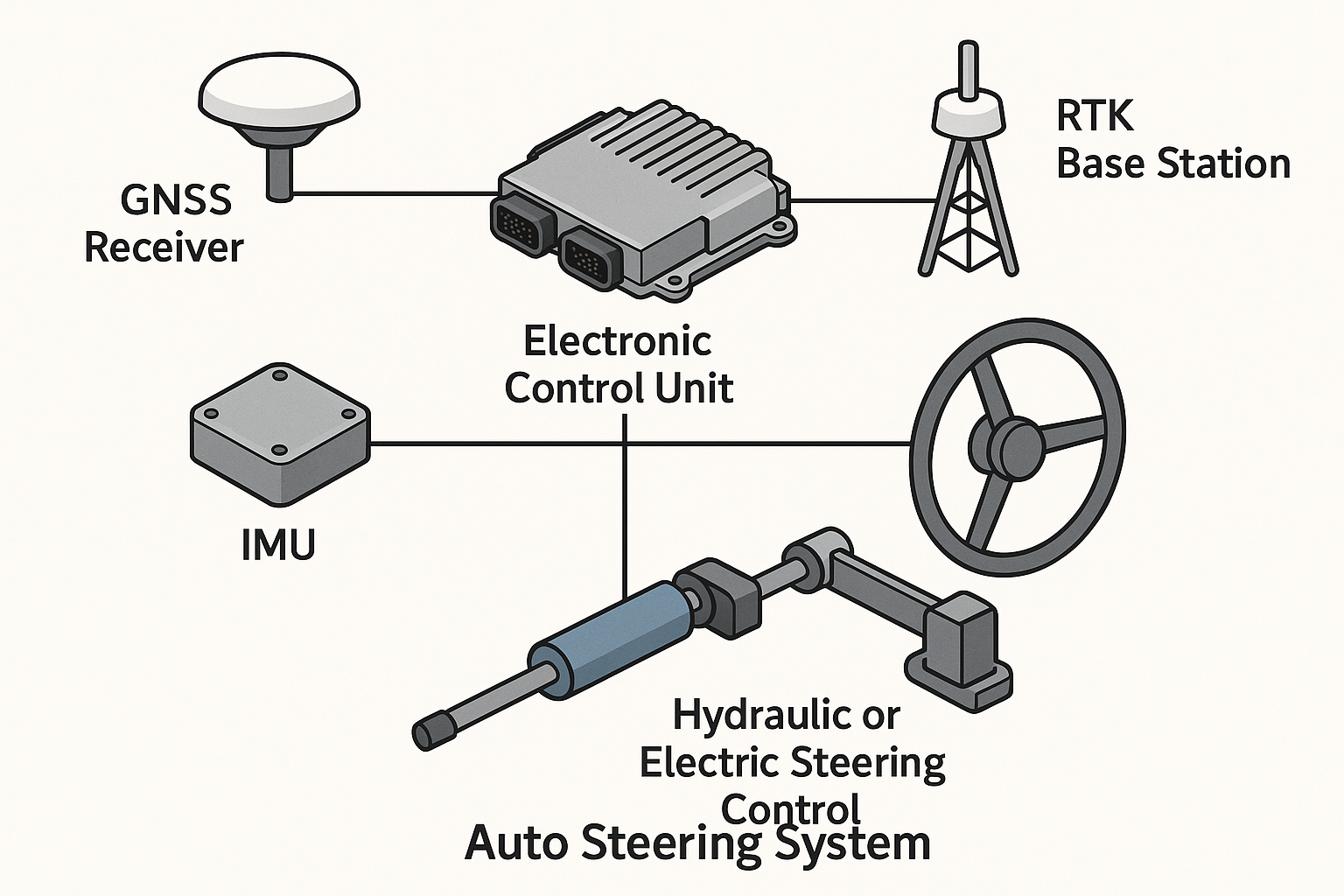

The auto steering system plays important role in precision agriculture. Based on satellite positioning (such as GNSS/GPS) and smart control technology. It enables tractors to drive automatically or assists with straight-line steering, replacing traditional manual operation. To improve operational accuracy and efficiency.

What does auto steer do?

- Positioning and Path Planning: The system receives satellite signals through a GNSS antenna (such as RTK precision positioning for centimeter-level accuracy) and generates the optimal work path based on farm maps.

- Real-Time Error Correction: While the tractor moves, the control unit constantly compares the actual position with the pre-set path. It calculates the steering angle through algorithms and sends instructions to the hydraulic valve or electric steering wheel to adjust the wheel direction automatically.

- Dynamic Execution and Calibration: The hydraulic system or motor drives the steering mechanism to ensure the vehicle follows the planned path precisely. Some systems also include inertial sensors (IMU) to maintain direction stability during brief signal losses.

For instance, in seeding, the auto steering system reduces 10%-30% overlap or skip, significantly reducing fuel, seed, and fertilizer waste. This machine has become the foundation of precision agriculture, helping large-scale farms reduce costs and improve efficiency.

Types of Auto Steering Systems

Two main types of auto steering systems are used in agricultural automation:

- Assisted steering systems: Help operators reduce manual errors. These still need driver supervision and are ideal for smaller farms or complex terrain.

- Fully autonomous systems: Use GPS navigation agriculture, RTK precision positioning, and IMU to enable unmanned operations. Suitable for large-scale seeding and harvesting.

- RTK systems use base stations to correct GPS signals, achieving centimeter-level precision, ideal for tasks like precision seeding and ridging. However, they rely on stable networks and cost more.

- Non-RTK systems (like single-point GPS) offer 1–3 meter accuracy, are more affordable, and easier to deploy. They are suitable for lower-precision needs. Choosing between them depends on task needs, farm size, and budget. RTK is becoming the mainstream in precision agriculture.

What are the benefits of auto steer?

Auto steering systems are profoundly changing traditional farming operations with their precision, efficiency, and sustainability. The core advantages include:

- Improved Operational Precision

With centimeter-level straight-line driving, the auto steer system significantly reduces the overlap, skips, and errors seen in manual operations. In seeding, fertilizing, or spraying, precise auto steering systems ensure uniform seed spacing and complete fertilizer coverage, minimizing resource waste while promoting even crop growth, leading to a 10%-20% increase in yield per unit area.

- Reduced Operator Fatigue

Traditional tractor operations require the driver to maintain constant focus, particularly during nighttime or large-scale continuous tasks, leading to fatigue and errors. However, the auto steering system reduces manual intervention, easing the physical and mental burden on operators.

- Improved Fuel Efficiency

By optimizing travel paths through planning algorithms, the auto steer system avoids unnecessary turns or repeated operations, reducing fuel consumption by 15%-25%. For large fields, precise straight-line operations shorten the total travel distance and reduce tire slippage and engine idling, directly lowering fuel costs.

- Significant Productivity Boost

The auto steering system allows for 24-hour continuous operation, overcoming the time limitations of human drivers. It improves work efficiency by more than 30%, especially during critical agricultural periods such as planting and harvesting.

Future Trends of Auto Steering Systems

The auto steering system is merging with AI, 5G, and IoT technologies, transitioning from automated control to intelligent decision-making. The future will see:

- Multiple autonomous machines working together

- Automatic obstacle avoidance and dynamic path adjustments

- Integration with drones and soil sensors for on-demand seeding and fertilizing

- Lower-carbon, more environmentally friendly precision agriculture solutions

For agricultural practitioners, investing in precision agriculture equipment is not only a way to improve efficiency but also a strategic decision to secure a position in the future of farming.

Conclusion: Is the Auto Steering System Worth the Investment?

For modern farms seeking high efficiency, low cost, and green production, investing in an auto steering system is not only a short-term strategy for increased productivity but also a key step toward precision agriculture. Its core value lies in improving operational precision, reducing resource waste, freeing up labor costs, and pushing agricultural production toward higher efficiency and sustainability.

From seeding to harvesting, the system can reduce seed and fertilizer losses by 10%-30%, increase yield by 15%-20%, and, with 24-hour continuous operation, drastically shorten farming time, creating significant economic benefits for large-scale farms.